Graphic Designs and Art on Custom Tile

Custom Design Tile: Full Color Printing

Art printed on ceramic, porcelain, marble and glass tile.

Architectural tiles serve hospitality, residential, and commercial needs. We have design studio and interior decorator experience, assisting with graphics project specifications.

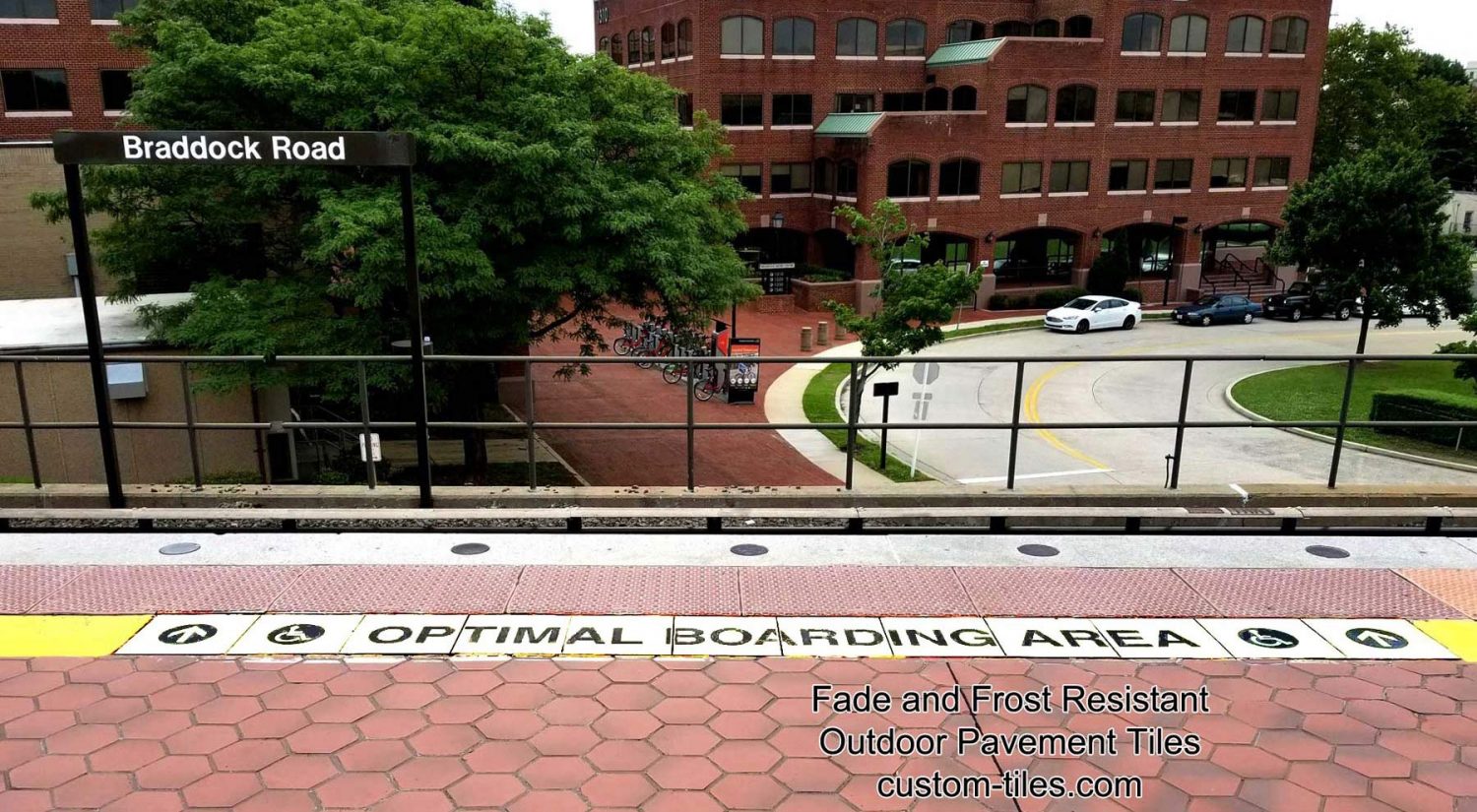

Graphic tile designs have extremely high traffic durability: useful for outdoor pavement and train platforms.

Use them as building facade tiles for their fade resistance with graphic art on exterior cladding.

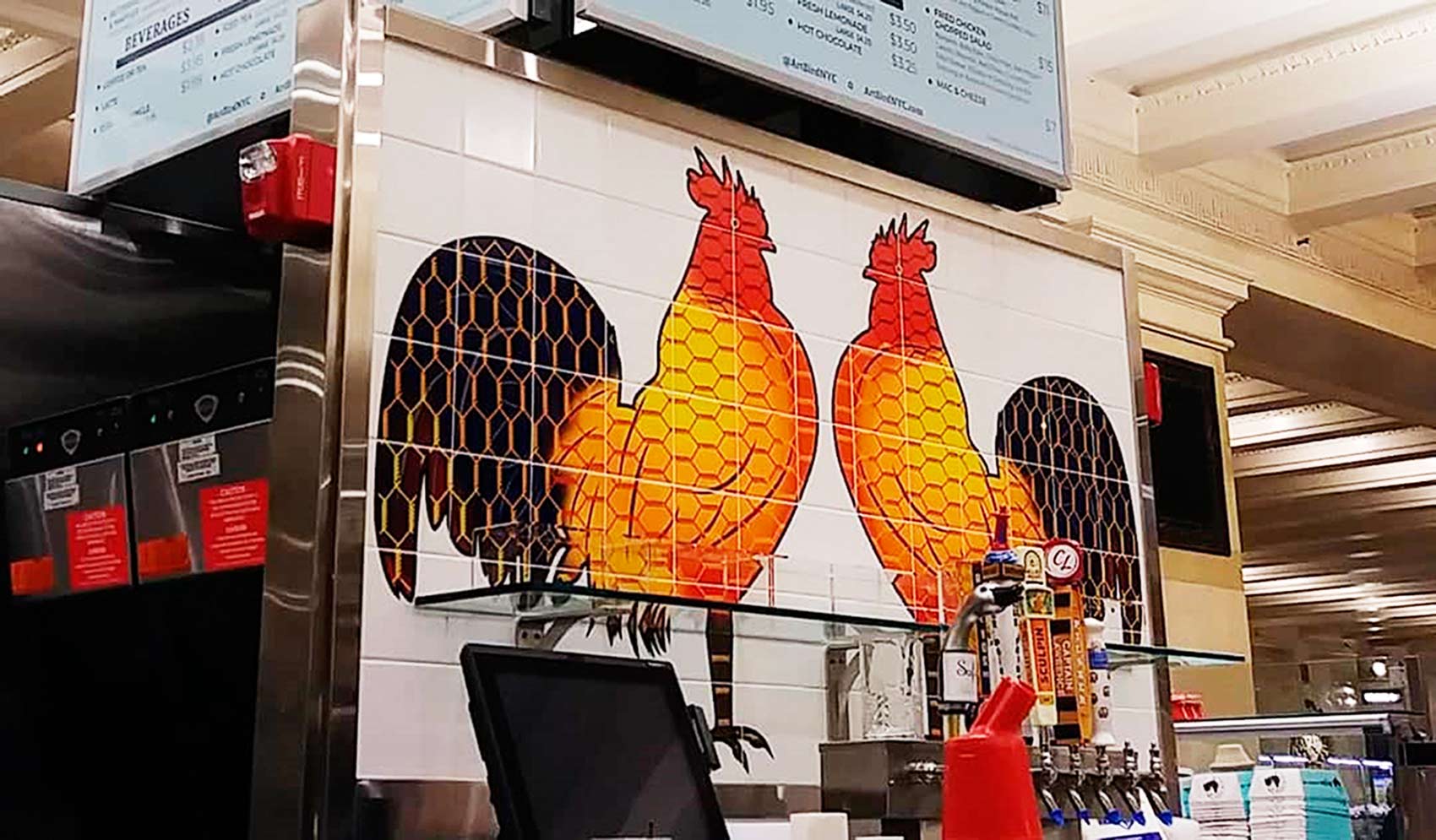

Graphic images serve to engage the eye and interest in shopping malls, restaurants, and other public venues. We can reproduce your graphics on tiles of various types. Consult with us for the best product for your purposes. From outdoor public art in extreme environments to interior residential kitchen backsplashes, we cover it all.

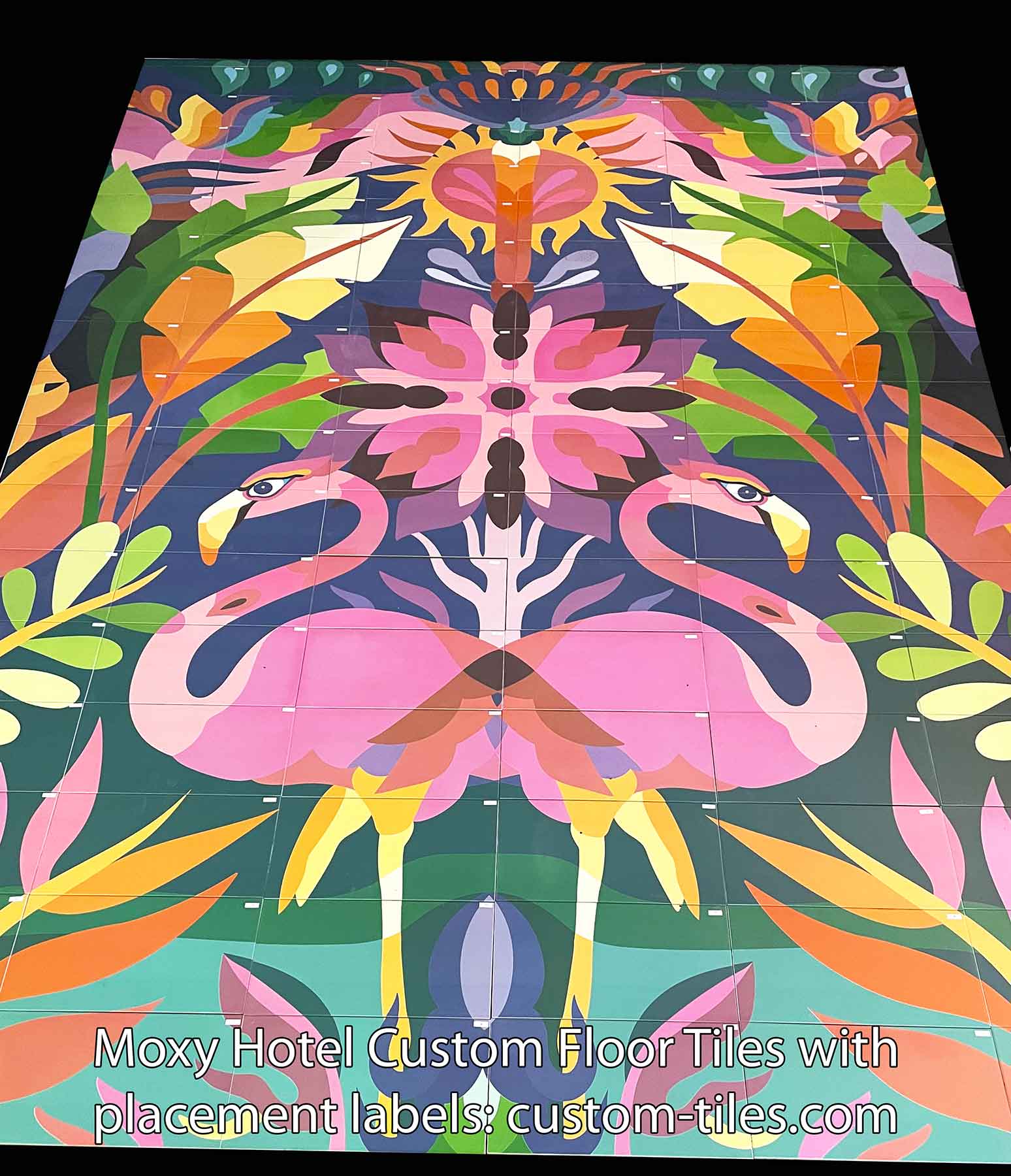

Interior design studio clients have specified Custom Tiles’ products for the best in unique graphics on colorful tile. We provide detailed specs and shop drawings. From Margaritaville hotels in CA & TN to food venues coast to coast, Custom Tiles, LLC has provided colorful hospitality decor with excellent service and on time delivery.

Custom Graphics Printed on Tile: Send us your artwork (photo, scanned art, logos, wayfinding text). You may choose wall tile or floor tile, and a choice or ceramic, glass, or porcelain tile. We produce for indoor and outdoor tile use and offer pre-production proof tiles for approval. You are invited to browse our portfolio.

Ceramic Printing Technology

Advances in ceramic tile printing have nearly closed the gap on ‘making all things possible’ for custom tile decoration.

CMYK dry pigment printing is still the benchmark for color strength, saturation, and substrate hiding-power. The gamut of inorganic pigments which have been incorporated in this approach has increased. For example, the magenta ‘slot’ can be filled with red-magenta or red in the printer reservoir. The ideal four-color selection (CMYK, CR-MYK or CRYK) will be determined by the artwork. There are also newly minted white, blue, and orange pigments run as single-color options.

Four colors were the limit as well for inkjet printers. Modern configurations feature as many as ten color banks. This allows a much wider color gamut. Mechanical improvements include ink recirculation and automatic head cleaning to avoid pigment settling and head clogging. The higher equipment cost is offset by lower maintenance costs and increased production. Multi-head printers can apply clear coats for gloss control and anti-slip properties.

Tile Cost & Project Requirements

Due to the level of technology involved, clients are often reliant on the supplier to fully understand the requirements of the project. It may not be obvious to the client what kind of trade-offs are involved by the various options. Color matching, color strength, resulting sheen, durability, weather/moisture exposure, production scheduling, and costs all factor into the decision for the appropriate method and substrate to be used. For example, to simply say “ceramic” does not express the specific properties of the tile Group (I, II, or III) or moisture absorption (E value), or shaping (pressed, extruded, or ‘other’).

We evaluate the project environment and recommend the best (and alternative, if available) tile type and print technology appropriate.