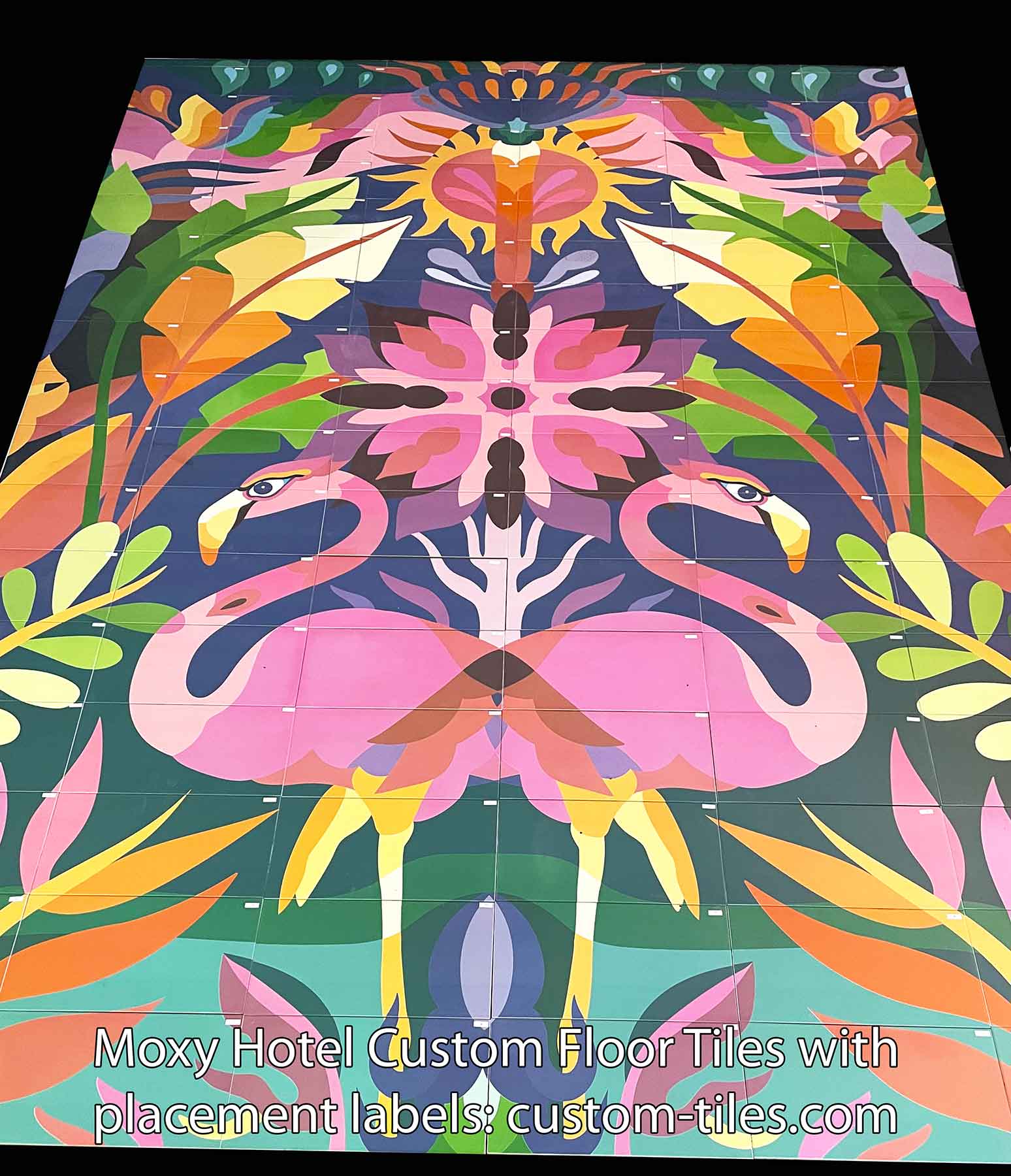

Custom Floor Tile - Residential, Commercial, Outdoor Pavement & Transit Platforms

Made to order custom designs on floor tile are available for high traffic areas. The decorated tiles are tough enough for transit platforms and outdoor sidewalks. You choose the design for the custom printed graphic floor tiles and send the image file to us for high resolution printing.

We offer a variety of tile compositions and print methods. Tell us your project details and learn the best custom flooring tile solutions.

Want to prevent slips and falls? We can guide you through the maze of regulations and documentation. Link to our Request for Quotation or email us. For the most rapid turn-around on small, interior projects, see Glass below.

Your artwork, text, or logo can be an attractive design element for your hotel, restaurant, home, or poolside/patio.

Custom Porcelain Tiles from Your Digital Images

Customized Porcelain Tiles for Indoor – Outdoor – Slip Resistant – or Glossy: Digital printing on fired tiles for murals and decorative tile for commercial and residential walls and flooring.

Regulations and Documentation

2024 International Swimming Pool and Spa Code (ISPSC) Exert:

306.2 Slip resistant.

Decks, ramps, coping, and similar step surfaces shall be slip resistant and cleanable. Where surfaces are evaluated for slip resistance, such surfaces shall have, when tested wet, a minimum pendulum slip rating classification of P4 if tested in accordance with SA AS4586 or a minimum Dynamic Coefficient of Friction (DCOF) of 0.42 [emphasis ours] if tested in accordance with ANSI A326. The design professional shall determine the appropriate classification and level of slip resistance necessary based on surface type, placement environment, and pedestrian traffic. Special features in or on decks such as markers, brand insignias, and similar materials shall be slip resistant.

ANSI A326.3 American National Standard Test Method for Measuring Dynamic Coefficient of Friction of Hard Surface Materials—2021

3.0 Specification

3.1 DCOF ≥ 0.42*: Unless otherwise declared by the manufacturer, hard surface flooring materials suitable for level 2 interior spaces expected to be walked on when wet with water shall have a measured wet DCOF value of 0.42* or greater when tested using SBR testfoot material and SLS solution as per this standard. However, hard surface flooring materials with a measured wet DCOF value of 0.42* or greater are not necessarily suitable for all projects. The specifier shall determine materials appropriate for specific project conditions, considering by way of example, but not in limitation, type of use, traffic, expected contaminants, expected maintenance, expected wear,3 and manufacturers’ guidelines and recommendations. 3.2 DCOF < 0.42*: When tested using SBR testfoot material and SLS solution as per the procedure in this standard, hard surface flooring materials with a measured wet DCOF value of less than 0.42* (including by way of example, but not in limitation, polished surfaces), unless otherwise declared by the manufacturer, shall only be installed when the surface will be kept dry when walked upon and proper safety procedures will be followed when cleaning the hard surface flooring materials. Hard surface flooring not intended to be walked upon when wet shall have a dry DCOF value of 0.42* or greater when tested per Section 10.0 of this standard. 1 The values determined by this test method reflect the dynamic friction between the testfoot and the hard surface.

3.4 Manufacturer-Declared Product Use Classification: … INFORMATIVE NOTE: Hard surface flooring materials with a measured wet DCOF value less than 0.42* are often used in areas such as shopping malls (outside the food court), hotel lobbies, office buildings, etc. where a certain appearance (e.g. glossy) and ease of cleaning are highly desired and measures are in place to keep the floor dry when walked upon.

4.1.4 Exterior, Wet: See Section 3.4. (Manufacturer-Declared Product Use): Product shall be manufacturer-declared for this category based on manufacturing parameters, internal quality control criteria, and manufacturer experience with similar surfaces. Attributes to consider include, but are not limited to, product size, texture, structure, and additionally in wet applications, drainage. Products meeting Exterior, Wet criteria may require frequent maintenance to keep clean. INFORMATIVE NOTE: Possible Areas of Use: Subject to determination by specifier and the criteria in this standard, may include, but are not limited to, level outdoor living spaces including pool decks, walkways, patios, and sidewalks, where such floors may be walked upon when wet (excluding ice or snow) if level, clean, maintained, and free of standing water or other contaminants.

Equivalency Note: The wet pendulum test method is used to determine the Slip Resistance Value (SRV) which is the mean BPN (British Pendulum Number) for the sample being tested. This BPN represents the dimensionless unit of slip-resistance that is used to generate a slip rating (P5 to P0). When converted, the SRV of 40 specified within Section 315.2 (Wet Pendulum Test Method) is equivalent to the DCOF value of 0.42 specified within Section 315.3.1 (DCOF, Level Walkways). Additionally, NSF/ANSI/CAN 50 requires ground level surfaces of aquatic water play venues to have a minimum P4 rating, or SRV of not less than 40 in accordance with AS 4586.

Product Use Classification

Classification | Reference Category | Criteria |

Interior, Dry | ID | ≥ 0.42 dry DCOF*1 (per Section 10.1) |

Interior, Wet | IW | ≥ 0.42 wet DCOF* (per Section 9.1) or Manufacturer-Declared |

Interior, Wet Plus | IW+ | Manufacturer-Declared |

Exterior, Wet | EW | Manufacturer-Declared |

Oils/Greases | O/G | Manufacturer-Declared |

Installing Custom Floor Tile

An important tip for the do-it-yourselfer: Brief tile installation video. Want to prevent slips and falls? We can guide you through the maze of regulations and documentation. Plan your project with us for professional guidance and the appropriate custom flooring solution.

For the most rapid turnaround when pressed for time, see information on custom interior flooring: Glass tile for walls and floors

Additional technical information links are here.

Interior Customized Glass Floor Tile and Medallions

Tile Council of North America testing lab results of our Glass Floor Tile (we also offer Porcelain Outdoor/Indoor Tiles):

ASTM C1028: Static Coefficient of Friction – Dry =.86 Wet =.52 (meets OSHA recommendations). The Building Code for the City of Los Angeles, California (USA) requires that level surfaces have a COF of not less than 0.6 and ramps have no less than 0.8 – these tiles exceed those requirements.

ASTM C648: Average breaking strength is 1931 lbf. Compare to approximately 250 pounds for regular ceramic tile. (https://www.thespruce.com/reasons-why-tile-floor-is-cracked-1822645)

ASTM C373: Water absorption rate of 0.37% = impervious

Digital glass floor tiles withstand chemicals such as paint removers , citrus-based cleaners, and foaming oven cleansers, providing graffiti resistance for walls and floors.

ASTM C650: Resistance to Chemical Substances: Not affected by the following: Acetic Acid 3% & 10% Ammonium Chloride, 100 g/L Citric Acid Solution, 30 g/L & 100g/L Lactic Acid, 5% Phosphoric Acid, 10% Hydrochloric Acid Solution, 3% & 18% Sulfamic Acid, 3% & 10% (Becomes sulfuric acid when mixed with water) Swimming Pool Chemicals (Sodium Hypochlorite Solution) 20mg/L Potassium Hydroxide, 30 g/L & 100 g/L

ASTM C485: Warpage of Tile: Edge warpage: -.02%, Diagonal Warpage: 0.00%

ASTM C499: Facial dimensions and thickness of tile – Average difference of 0.020 inches

ASTM C502: Wedging of Tile – Average percent wedging was 0.03%

ASTM C1026: Tiles showed no evidence of damage after completing 15 freeze/thaw cycles.

Custom Floor Tile Restriction: Not for installation in direct sunlight! For complete fade resistance: use our outdoor tile.